Share

Pin

Tweet

Send

Share

Send

In addition, not every company has professional installers who can provide truly high-quality installation. At the same time, installing a plastic window is an affordable event.

Measurement and dismantling

If you decide to install the window with your own hands, then you will have to do the measurement yourself. This is a very important stage, so you will need to try. Take off the dimensions so as to leave a small gap on each side (1.5-2 cm). During installation, this will allow for fitting and good foam window. Also, do not forget that the installation of the frame is carried out strictly according to the level. Therefore, be sure to make sure that your slopes are not overwhelmed. In this case, you have to choose: order a window for a smaller size, or cut the slope before installation.

When the finished window was delivered to your home, you can begin to dismantle the old one. You will need to remove the old frame, box, windowsill. Also carefully inspect the slopes. In the presence of residues of poorly adhering plaster, they must be completely removed.

Preparing a window for installation

Before installing a window, it must be prepared. You will need to install a handle on the sash. Then you will need to remove the sash. To do this, you will need to remove the pin from the upper loop. To start, lightly tap it with a hammer in the direction from top to bottom. When the pin moves, it can be removed using pliers, or knocked out with a screwdriver. After that, it is enough to turn the window handle to open, which will allow you to easily remove the sash.

The next step is to install the mounting plates. They are attached to the frame using self-tapping screws. As a rule, on the front side of the window frame there are already prepared holes for mounting plates with self-tapping screws. However, often the length of these screws is insufficient. Therefore, you may need to take longer fasteners. Mounting plates must be installed at the top and bottom of each side pillar of the window frame. Another one or two plates are placed in the middle of the rack. You can also put one or two plates on the upper bar. When installing, please note that the long part of the mounting plate should be directed towards the inside of the window.

Window mounting

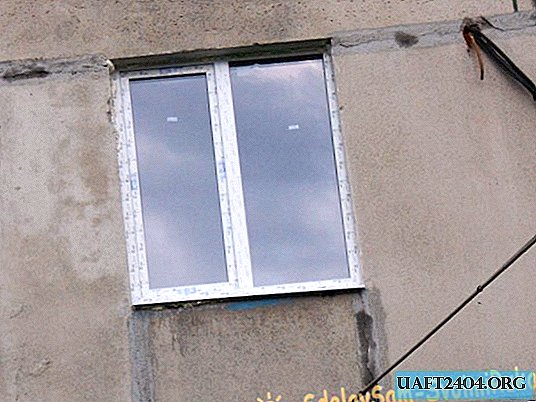

The prepared plastic window frame is installed in the opening. It is first necessary to prepare a sufficient number of wooden wedges. The lower plane of the frame is mounted on wedges, which allows you to leave the gap necessary for foaming.

The frame installed in the opening must be wedged. For this, cooked pegs are used. During the wedging process, the position of the window in the opening should be adjusted. Using the building level, you should carefully check the correct installation in each of the planes. The position of the frame is fixed with wedges. The wedged window should not stagger, remaining in the position prepared for installation. At the same time, when wedging, avoid strong blows to the pegs, otherwise the frame can be deformed. In the most unpleasant cases, with inaccurate driving of wedges, the profile may burst.

After the frame is wedged in, you can proceed to fasten the mounting plates. In the right place of the slopes with the help of a puncher, holes are prepared. The dowels are clogged into these holes, which will hold the mounting plates.

When the frame is completely fixed by the mounting plates, you can install the sash and check that it is freely closed, opened and tilted. In case of proper installation of the frame according to the level, this installation step should pass without any problems.

Foaming

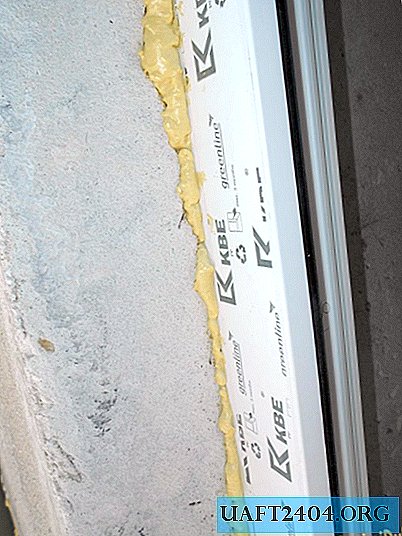

The final stage of installing a metal-plastic window with your own hands is foaming. All mounting gaps that should have been well filled with mounting foam around the entire perimeter. Before this, it is better to pre-moisten the places on which the foam will be applied. For a higher installation quality, it is recommended to choose a professional foam under the gun.

After foaming, the window cannot be opened until the foam completely hardens. This usually takes about a day. When enough time has passed, it is recommended once again to make sure that the window is working as it should. After that, you can remove the protective film, cut off the excess foam and proceed to the decorative finish of the window slopes.

Share

Pin

Tweet

Send

Share

Send