Share

Pin

Tweet

Send

Share

Send

There are a number of ways to reverse sulfation, a process called desulfation. I will tell you how to assemble an electronic device that can desulphate battery plates with electrical pulses.

Advantages of the electronic method of battery recovery

To restore the battery does not need to be subjected to any disassembly, which is so important when restoring non-separable or gel batteries. It does not even need to be removed from the car when it comes to a car battery.

This recovery method is effective in 80 percent of cases - and this is a very good percentage.

In time, the method is not costly and will take you no more than 24 hours.

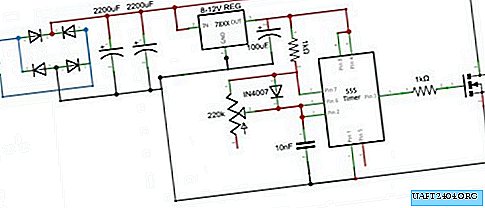

Electric circuit

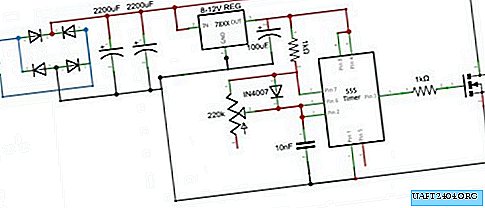

The scheme is not intricate. On the left is a rectifier bridge with smoothing capacitors. Next comes the stabilizer on the microcircuit, which powers the master oscillator assembled on the 555 timer. The timer, in turn, controls a powerful field-effect transistor that switches the battery to the power source.

The whole circuit is connected to a rectifier transformer, with an output of the secondary winding of 15-20 volts AC. The voltage is rectified into direct current up to 20-25 V. This will be the main voltage that will be supplied to the battery. The master oscillator generates very short pulses of high frequency, somewhere around 10-35 kHz. By means of a transistor switch, these pulses arrive at the battery.

Operating principle

The device gives the battery short pulses of high amplitude. The peak, which can reach 10-25 A. Under the influence of these pulses of high frequency and high amplitude, ion electrons are excited, which in turn destroy lead sulfate, and the battery regains its capacity.

This recovery method is very effective and helps to bring to life, it would seem, almost "dead" batteries.

Assembly of the desulfation device

You can assemble the circuit on the breadboard. Transistor will not be superfluous to install on a small radiator.

Battery Recovery Process

In any case, before starting to restore the battery, it would be nice to check the presence of electrolyte in the banks. And, if necessary, add distilled water.

Well, then we connect to the battery as a normal charger and periodically monitor the charging process, measuring the voltage on the battery.

The whole process can take you from 1 hour to 24 hours, it all depends on the battery capacity. Naturally, for car batteries it will be more. It is also possible for a battery with a large capacity may require a more powerful mains transformer with a higher voltage.

A variable resistor controls the pulse frequency. By rotating which, experimentally, they achieve the best recovery results.

For all the time I managed to restore more than one battery. The device is suitable for both 12 volt batteries and 6 volt batteries.

Watch the video

Share

Pin

Tweet

Send

Share

Send