Share

Pin

Tweet

Send

Share

Send

Making yourself a classic sleigh according to all the canons will be quite difficult and will take a lot of time. And in terms of costs, it can fly a pretty penny.

Another thing is a non-standard product, which in terms of reliability, capabilities and safety will not yield to the factory device. After all, making sledges with your own hands, you can find the original design, be creative in creating each element and operation, come up with some options. As a result, you can get a real masterpiece, which does not take so much time, labor and money.

Of course, children will be especially delighted with homemade products. What a joy a whole company rushes on such a sled from a hill - an indescribable, breathtaking, descent that will remain in your memory for a long time! So what is needed for this?

Necessary materials and tools

For our idea, inexpensive materials and a tool not too complicated to use are suitable:

- one 200-liter plastic barrel;

- a wooden beam with a section of 38 × 89 mm and 30 × 70 mm;

- screws or wood screws with a wide hat;

- synthetic cord or thin rope;

- varnish and paint brush;

- anti-slip material (for example, rubberized floor mat);

- paraffin wax;

- gas-burner;

- metal square;

- drill with 2 drills with a diameter of 7/8 and 1/2 inches;

- band-saw;

- hand screwdriver or screwdriver.

Manufacture

We begin by considering the elements that determine the design, in particular, the size of a mountain sled.

The main elements of the sleigh

A sliding surface with a width of about 560 mm can be cut from a standard plastic barrel, the outer diameter of which is 580 mm. A turn of such a circle will give the length:

C = πD = 3.14 × 580 = 1820 mm.

If the front bend takes about 300 mm, then the horizontal part will be about 1520 mm, which is enough to accommodate 3-4 children. The indicated dimensions will be specified as work progresses on the sled.

The price of a new 200-liter barrel is about 2100 rubles, a used capacity, for sure, can be bought for 500 rubles or cheaper. If something oily was stored in it, then it can be easily washed with detergents. Sometimes they are stored in such barrels. Then the container will be clean by default.

For the side elements of the sled, we will choose 2 dry wooden blanks with a section of 38 × 89 mm and a length of about 1530 mm from oak, birch, maple, etc. The front cross members can be made of 2 blanks with a section of 30 × 70 mm and a length of 560 mm.

Barrel marking and tool for this

To cut the sliding base of the sled, you need to mark the side surface of the plastic barrel. To do this, we need a homemade thicknesser. It can be made from a rigid wooden block with a length of ⅔ of the height of the container.

After measuring the height of the barrel, and the selected width of the sled (560 mm), we mark a place on the thicknesser and drill a hole for the marker. To its upper end we securely fasten the limiter, which will slide along the lid and the bottom of the barrel, and the marker will draw two circles. It remains only to draw a vertical line between them.

Barrel Cutting

The reference points for cutting will be the holes at the points of convergence of the marking lines made by a 6 mm drill. The most convenient for cutting barrels is a jigsaw, although you can also use a grinder.

To keep the barrel stiff, first cut it in circles, separating the area of the lid and bottom, and only then the middle part of the workpiece in a vertical line.

Edges can be slightly treated with a file on a tree or with a sharp knife, removing the roughness remaining after cutting.

Straightening a plastic blank

The workpiece, representing the middle part of the barrel, should be straightened, and the inside should be turned outward, since it is smoother compared to the outside.

Often on plastic barrels make stiffeners with a protrusion outward. When the inner side bends toward the snow, these longitudinal gutters play the same role as on the sliding surfaces of skis or snowboards. They will provide sled travel stability.

To straighten the workpiece, we lay it out on a flat surface and press it in several places with bricks or buckets of water, and leave it for a while. Then the workpiece can be twisted in the opposite direction and also hold in this position for some time. As a result of these manipulations, she will straighten enough. Minor irregularities will be removed in subsequent operations.

Elements for a sleigh made of wood

As we already determined in step No. 1, we need two wooden blocks with a section of 38 × 89 mm and a length of 1524 mm (final size). Lateral force elements will be made of them, the role of which in the construction of toboggan is no less important than the sliding surface.

We will also need two bars with a section of 30 × 70 mm and a length of 560 mm. We will install one at the front bottom between the sidewalls to give strength to the whole structure, and the second at the end of the bent part of the plastic. The ends of the cord will be passed through it to transport the sled. Moreover, the nodes on the outside of the plank will ensure the constancy of the bending of the front end.

Side element processing

For a better glide in the snow, these wooden parts must be rounded in front. To do this, you can cut out a template from thick cardboard, attach it to the board and draw a marker around it.

The same needs to be done at the rear, but in smaller sizes. This will allow you to pull the canvas to the bars so that it does not slow down the movement.

We cut off the markings with a band saw or carefully plan with a sharp carpentry hatchet and finally finish the file with wood.

Marking holes for pens

The number of handles on each side may be different. We settled on three. Any way is suitable for their marking:

with the help of a template - a wooden bar with smooth ends, the length of which is proportional to the distance between the holes for the handles;

using a metal ruler and marker.

Drill holes for handles

To do this, you need a drill and two drills: one with a diameter of 22.2 mm, the other - 12.7 mm. In this case, the diameter of the synthetic cord or thin rope is chosen equal to 9.5 mm.

First, we drill 2 large holes on the face of the workpiece to a depth of 25.4 mm vertically one below the other, leaving a jumper between them approximately equal to the diameter of these holes. Then, from the side of the upper end, we drill holes with a smaller drill until large sockets are connected to each other.

We make exactly the same holes, retreating from the front edge of the boards by 152 mm. They will be needed to pass the ropes that will hold the front of the sleigh with their knots and serve as a tugboat.

Finishing work on wooden parts

So that the wooden parts do not get wet when in contact with snow, they should be covered on all sides with several layers of urethane varnish with a small paint brush, following the instructions on the can.

After the next layer of varnish has dried, it can be lightly treated with sandpaper No. 220 to remove roughness and sag. The result is very smooth surfaces.

Improving the look

You can make blue stripes along the side elements. To do this, cover the entire surface with adhesive tape, except for the contour of the strip. So that the paint does not leak under the tape, it can be coated with colorless varnish.

It remains only to spray blue spray paint in several layers and remove the protective film. The clarity of the outline of the strip will be impeccable.

Handle and tug preparation

We make blanks for pens with a length of about 610 mm from a braided synthetic cord with a diameter of 9.5 mm. To make it easier to work, we mark the cut points by winding a narrow tape, and we carry out the cutting with a carpenter's knife in the middle of the tape.

For the tow rope, we use two cords with a length of about 1520 mm. On all the blanks on one side we tie a knot using pliers. For reliability, the components can be lubricated with super glue before installation in the socket, but this is not necessary.

Place handles and tow ropes in place

At step 8, we have already prepared a system of holes for the handles and the tow rope. Pull the free end of the cord through a large hole into a small one and pull it up strongly so that the knot is additionally tightened and sits in its place. Then push the same end from above into the small hole until it appears in the big one. We pull it out and tie a knot. Now it is enough to pull the handle up so that both nodes are strengthened and take their place.

We do the same with two ropes designed to hold the front of the sled and tow.

Front edge mount

This transverse beam gives the sled a stiffness, helps preserve the bend of the front end, supports tow ropes and even serves as a means of controlling the sled.

It is applied to the plastic from the outside, pre-drilled into it several holes in advance, and fixed with screws 15 mm long. There are already 2 holes with a diameter of 12.7 mm on the sides of this beam for skipping the tow rope.

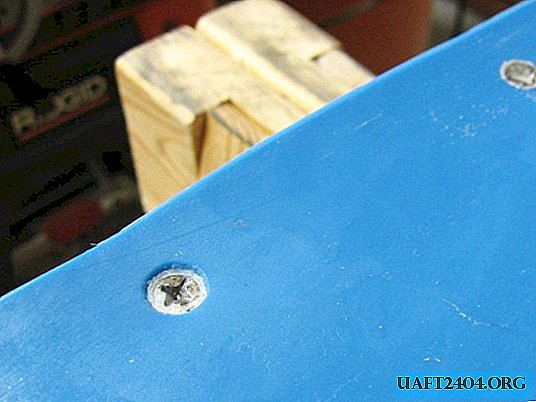

Attaching side bars to a sliding surface

For a solid connection of the main parts of the sled, the side rails are laid on the carpentry goats, a thin anti-slip cloth is placed on them and everything is covered with sliding plastic.

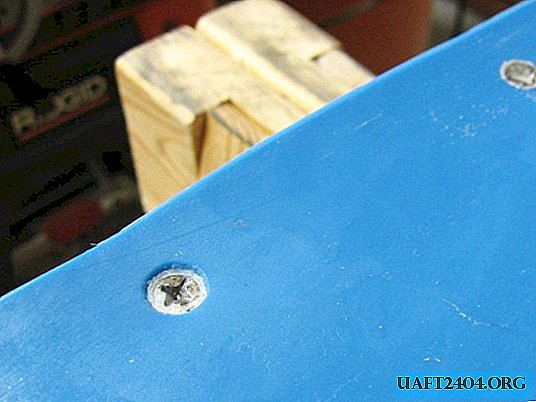

Then it is necessary to mark the places of tightening of screws with a length of 40-50 mm with a wide head. Installation step - 115-120 mm, preventing screws from getting into the holes for the handles and the tow rope.

We turn the screws from the center to the edges. This will smooth out the last small transverse bumps on a plastic basis. Screwing in the next screw, close together all the parts with a clamp.

Front beam installation

It is fixed at an angle due to the plastic surface starting to bend in this place. This bar is fastened from the ends with three strong screws 75-80 mm long on both sides. In front, it is seized in 9-10 places with screws 40-50 mm long through a plastic bend.

This beam gives the sled lateral stability, preventing the side elements from moving outwards or inwards. It also strengthens the curved part of the plastic web, which is experiencing heavy loads.

Towing line installation

Halves of the towing edges pass through the side holes in the upper bar. Depending on where we tie the knots, the front of the mountain sleigh will be raised and curved. The ends of the ropes are connected, and a tow rope is obtained.

Another option for installing a non-slip mat

The first and more successful version of its fastening is described in step 14. If you forgot to put it, then the anti-slip coating can be cut in place and glued from the inside to the plastic with adhesive suitable for these materials. Otherwise, on bare plastic, after getting snow on it, there will be quite a lot.

Waxing

Wax improves the sliding of plastic in the snow. With a piece of this material, thoroughly rub the entire sliding surface, especially the screw head. Then heat the wax-treated plastic with a gas burner so that the wax is more evenly distributed over the surface and into the recesses of the screws. It is advisable to do this operation before each day of skiing. The result is stunning!

Improvements and tips (instead of a conclusion)

After analyzing the work done, it turned out that the design can be finalized and improved. Let us state them in thesis order:

- You can make a semicircular shank;

- instead of 28 large blind holes on the sides of the side elements, you can do 14 combined ones - wide from below by 1/3 of the height of the beam and narrow from above;

- ferrous metal screws are best replaced with galvanized or stainless steel;

- some wavyness of the sliding surface is not terrible, because when several people sit in the sleigh, it is smoothed out by their weight;

- you can put more crossbars for increased strength and even seating for convenience, but this will make the product heavier. Let everyone choose what they like.

Original article in English

Share

Pin

Tweet

Send

Share

Send