Share

Pin

Tweet

Send

Share

Send

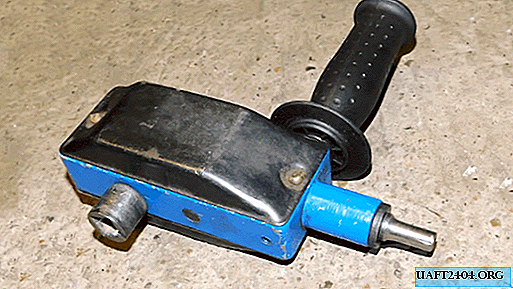

Everything is much simpler! To restore this part of the tool, you only need a piece of polypropylene pipe. The handle will eventually be round, and this is another useful feature of this homemade product. Let's get started?

Necessary resources for work

- A piece (several can be) of a polypropylene pipe without reinforcement (foil or fiberglass), diameter - 20-25 mm.

- Tank for melting polypropylene.

- A piece of board 40-50 mm thick.

Of the tools we need a drill, a drill according to the diameter of the handle of the processed tool and a pen drill, respectively, according to the diameter of the handle pipe itself. We select the length of the plastic pipe under the width of our brush and the required tool. You can still prepare a bolt with a round hat, close in diameter to the pipe.

Making a handle from a plastic pipe

First, prepare a wooden bed for our workpiece. We make a recess with a pen drill about 1-1.5 cm on the surface of the board, and then drill through the center of the hole for the handle of the tool. In such a simple way, a piece of pipe with a handle can be firmly fixed in the board.

Next, you need to prepare polypropylene for melting. The most unnecessary waste from scraps, defective fittings or dismantled obsolete plumbing fittings will do. Waste sealed dishes are suitable for a melting tank. Insert the handle of the instrument and the pipe into the holes on the wooden frame. You can immediately arrange several test specimens by adjusting the depth of planting of the handle in the handle.

After that, pour the molten polypropylene into the pipe. It cools quickly enough, and gives some shrinkage in the end.

While the casting is not frozen, the end face of the handle can be plugged with a regular bolt with a round smooth hat. After cooling, we pull out the workpiece from the bed.

If the handle is too long, it can always be cut with a hacksaw for metal. The chilled handle is easily processed with a knife and sandpaper.

Such a handle is not afraid of temperature changes, water and even hammer blows!

Practical tips

- It is necessary to work with hot polypropylene in tight protective gloves, otherwise, with careless handling, you can cause serious burns;

- The melting point of polypropylene is slightly more than 150 degrees Celsius, so it must be melted very carefully, avoiding open sources of fire. This is especially true for gas stoves. It will be safest to cover the container with a lid during heating.

Share

Pin

Tweet

Send

Share

Send