Share

Pin

Tweet

Send

Share

Send

But it should be noted that hardening, along with hardening of the metal, leads to an increase in its brittleness.

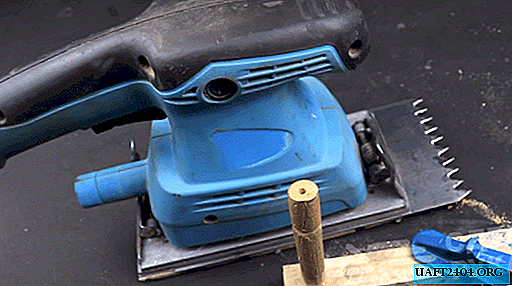

Here is a screwdriver with a broken tip. This occurred either from the large torque applied to it, or from improper hardening, which caused increased brittleness of the metal.

We will see how to harden steel correctly, so that it becomes strong and not too fragile, and be sure of this. At the same time, tools such as chisels, chisels, etc. must still have a sharp working edge.

Will need

For work, we need the following materials and tools:

- a container of water;

- gas-burner;

- mechanical emery wheel;

- file;

- 220 grit sandpaper;

- magnet.

Water for cooling steel after heating is often replaced with various oils and salt formulations. And with a magnet we will check, along with the color changing when the steel is heated, a sufficient hardening temperature, because when it is reached, the hot metal loses its magnetic properties.

That is, a specific color and the absence of magnetization are sure signs of the end of steel heating and its cooling in water.

Do-it-yourself screwdriver hardening

To harden the screwdriver, first we use a file and a grindstone to form a new end, because after hardening, the steel hardens so much that the file simply glides along without cutting metal.

If the damage to the tip of the screwdriver is small, then you can do without hardening. It is enough to process it on the grinding wheel for no more than two seconds and immediately cool in cold water.

With a gas burner we heat the end of a screwdriver with a newly formed sting. It is seen how, when heated, its color changes, which is important for quenching. We also check the readiness of the tool for quenching with a magnet. It ceases to be attracted to metal when the temperature reaches 760 degrees Celsius, and it needs to be quickly cooled.

After cooling in water, it is clear that the screwdriver is covered with soot, which is removed with sandpaper.

This is necessary for the tempering process in order to observe the temperature by the tint colors that the oxides take and to cool the screwdriver in time.

To heat the tool without a plastic handle to 260 degrees Celsius, we can use an electric furnace, placing it there for 20 minutes. Then, grabbing a pair of pliers, lower it into the water.

Under the influence of a gas burner flame, the color of the screwdriver changes from light yellow through others and turns purple, then dark blue, reaching the tip of the screwdriver. This color becomes a signal to stop heating and cooling the screwdriver in water.

The same blue color will be a signal for the end of heating of springy steel, since its temperature will reach 288-316 degrees Celsius, while the violet color indicates a temperature of about 260 degrees Celsius, used to temper the metal if it has become too brittle.

To release the knives, we heat the blades to a discoloration from light orange to dark yellow, i.e., to a temperature of 148-177 degrees Celsius. Assume another light yellow color, after which the knife is cooled in water.

We temper the tip of the screwdriver. When heated, a light yellow color appears first, then yellow, violet, when approaching the tip - light blue and finally dark blue, after which the instrument is lowered into water.

We do the same with a blunt chisel, starting with a file sharpener, and then temper when the end turns purple. We warm it carefully so as not to overheat the tip.

Warming up from top to bottom. First, yellow appears, then successively orange, purple and blue. After that, cool and clean the chisel with sandpaper and a grinding wheel.

Share

Pin

Tweet

Send

Share

Send