In this review, the author makes a do-it-yourself bending machine for the garage and home workshop.

You can bend on it not only the reinforcement, but also round and square rods, strips, etc.

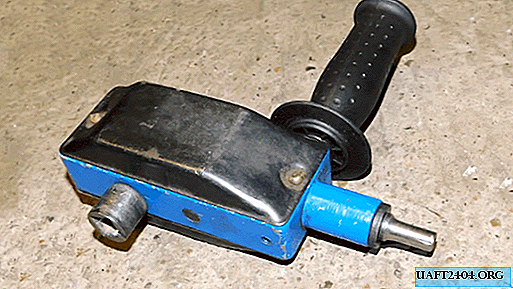

The arm bender consists of two main parts. The lower part is the base. Made of 200x150 mm plate and 4 mm thick.

A bar of 20 mm is inserted into one of the holes in the base (it is better not to take less), and scald.

The upper part is made of a piece of channel. Instead, you can take two corners, and weld them - and you get the same channel.

DIY rebar assembly

From two pieces of a round rod and a piece of a round pipe, you need to weld a handle. She puts on a bar of 20 mm, which is welded to the base. A lever is then put on the handle.

Assembly of the device is very simple. A bar is inserted into the hole in the base, and scalded. It is important that it is at an angle of 90 degrees.

A handle is put on the bar, then everything is closed by the upper part. The channel is welded to the plate (base).

Then we weld the second persistent "finger" to the channel. You can grab it first from the outside, so that it is easier to align along the axes.

On the third "finger", which is welded to the handle, put on the bearings, and the homemade product is ready. It remains to put on the handle the lever itself from the round pipe.

For details on how to make a rebar for a workshop with your own hands, see the video.