It will be much more convenient to process various metal blanks on an emery machine (electric grinder) in a home workshop or in a garage if the workplace is properly organized.

For example, in this review, the author shows how you can make a simple table out of improvised materials with an emphasis for an emery machine that can be adjusted at different angles.

First of all, the master puts on a emery a thick grinding wheel from the angle grinder, fixes it with a clamping nut. After that, he cuts off the protruding part of the shaft, since this "tail" will interfere with the installation of the table.

The main stages of work

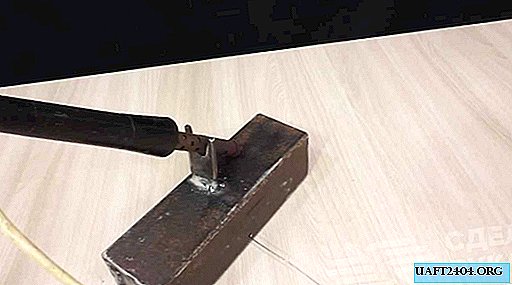

Further on the sides of the platform on which the emery machine stands, the master fastens two channels. If they are not at hand, then you can simply weld together two pieces of the corner.

The next step is to cut off another piece of the corner. At the edges of the master welds two "plugs" cut from a piece of plate. Moreover, they first need to drill holes.

Then the master fastens two strips of metal to the "plugs". The resulting design is set at the right angle relative to the emery machine, and is welded to the channels.

The table itself is cut to the desired size from sheet metal 3-4 mm thick (thicker, but not necessary). Then the rotary stop from a piece of the corner is attached.

You can see the detailed process of making a table with an adjustable emphasis for an emery machine in the video on the website.