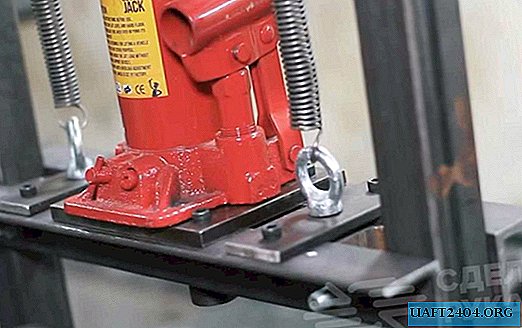

In the process of processing various parts and blanks of metal in a workshop or garage, it is often necessary to use the pressing method.

For this, as a rule, a special mechanism is used - a press. But factory models are expensive. Therefore, it is easier to make it yourself from a car hydraulic jack of bottle type and improvised materials.

Homemade mini press from the jack is not only low cost, but also compact in size, which is very convenient, because it can easily be placed even in a small room.

The main stages of work

First you need to cut the metal blanks that will be used in the manufacturing process: sections of the profile pipe and angle. Then the master makes a marking and drills holes in all the workpieces.

At the next stage, the master starts assembling the main part of the construction of a homemade mini press. To do this, he connects the corners and segments of the profile with bolts and nuts. Then you need to cut the plates and drill holes in them.

Next, a “sole” is mounted from a thick piece of metal, two springs are attached and an automobile hydraulic jack is installed. Now the homemade product is ready - you can try it in work.

For more information on how to make a mini press from a bottle jack for a car, see the video on the website.