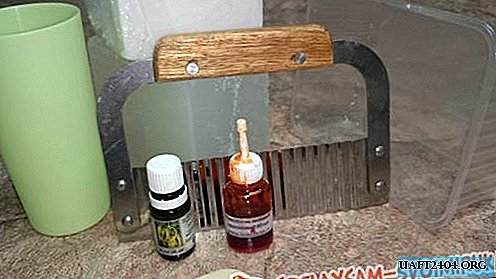

Using a simple home-made tool, you can cut polystyrene and expanded polystyrene using the hot method. Using this homemade product, you can quickly cut out various shapes that cannot be cut with a clerical knife "on the cold."

First of all, it is necessary to prepare the basis on which all the main elements will be placed. And for this, the master cuts out a piece of suitable size from a plywood sheet, and then polishes its outer surface.

Next, you will need to make markings and drill four holes in the plywood, into which the master then screws 4 rubber legs around the edges. Thus, the homemade base will be more stable (especially on smooth surfaces).

The main stages of work

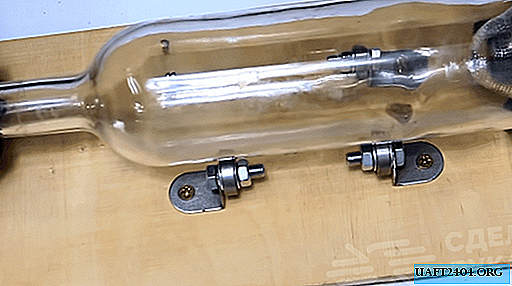

At the next stage, it will be necessary to drill two more holes along the edges of the base (on the axial center line). Long bolts are inserted into these holes, to which the master connects the wires.

It will also be necessary to fasten a metal corner to the plywood, in which several holes must first be drilled - for fasteners and bolts. This structural element acts as a wire tensioner.

At the last stage, 0.3 mm thick nichrome wire is attached to the bolts and the tensioner, which will cut the polystyrene and polystyrene foam.

For the detailed process of making a homemade device for hot curly cutting of polystyrene, see the video on our website.