If you have an old emery on hand, you can easily upgrade it. What is it for? Well, for example, to use the machine for convenient processing of various wooden and metal workpieces using grinding wheels with a pile on the back - for Velcro discs.

And the modernization process is very simple. You will need to make a couple of circles on the motor shaft, on which grinding wheels with Velcro will be attached. And also additionally you can make platforms on the sides of the machine. The main materials for work are plywood and MDF.

First of all, it is necessary to cut off the square blanks from MDF, glue them in two pieces and fix them with self-tapping screws. This will be the basis for the manufacture of circles that are worn on the shaft of the emery machine electric motor.

Step-by-step upgrade process

After the glue has dried in the center of the workpieces, it will be necessary to drill holes for the washer and nut. Then the corners of the square need to be cut off, and the rest should be polished so that in the end a circle shape is obtained. Although, it's easier to just cut the circle with a jigsaw, and then trim.

On the front surface of each disk you need to stick the Velcro tape, to which grinding wheels will be attached.

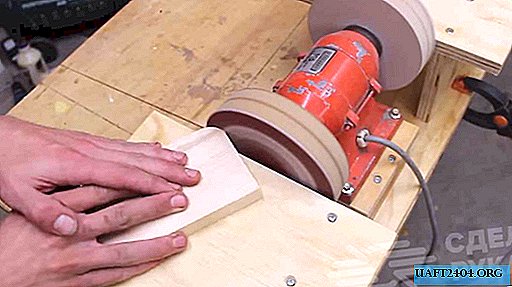

Then the MDF discs are mounted on the motor shaft. And the emery machine itself is attached to a stand made of plywood.

At the last stage of the work, it remains only to make platforms on both sides of the emery. In this case, it is desirable to make them rotary, so that it is convenient to change the grinding wheels. For details on how to whip up an old emery machine, see the video on the site.