As a basis for the countertop, massive oak driftwood is used, sawn into two parts and adjusted to the desired size. In two halves, it is necessary to use a hand milling cutter to make a recess of square shape. Then the surface is impregnated with mineral oil.

At the next stage, a rectangular "formwork" is made of plastic of the required width and length into which the tabletop is laid. Then everything is poured with epoxy resin with a white dye. In the same way, you will need to make the table leg. To do this, first three square shapes are made, small oak "stumps" are laid in them, and then everything is filled with white epoxy.

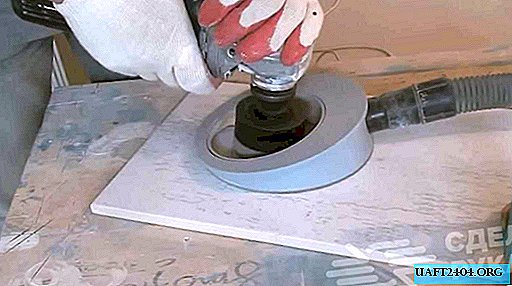

After pouring, it is necessary to allow the resin to completely harden - this will take on average about 7-10 days, depending on the thickness of the layer. Next, you can proceed to the mechanical processing of countertops and foot elements. This will require a hand mill, grinder and lathe. Three balls must be made from the squares, which are then connected to each other by means of a stud with a nut.

Finishing and assembling the table

After all stages of machining, final grinding and table assembly are carried out. The two halves of the countertops are connected at right angles with the help of furniture corners. Then a hole is drilled for a nut with a stud, on which three balls are put on - this will be the table leg. The nut is filled with epoxy for reliability.

The surface is coated with mineral oil or colorless varnish. The result is a very nice table made of oak and white epoxy. A detailed process of manufacturing and assembling this unusual table, see the video on our website.