Electric drill is a universal home tool, the functionality of which can be constantly expanded. For example, using a special end nozzle and a homemade device, you can make a simple design that is useful when processing plywood or chipboard to even the edges of the sheets after sawing, as well as round the corners.

For the manufacture of a home-made wooden stand, as well as a grinding nozzle for an electric drill for processing the end edges of sheet materials and wooden workpieces, affordable and inexpensive materials will be required: plywood sheet, bolt with nut, self-tapping screws, glue. It takes a minimum of time to assemble the structure.

The process of making nozzles and stands

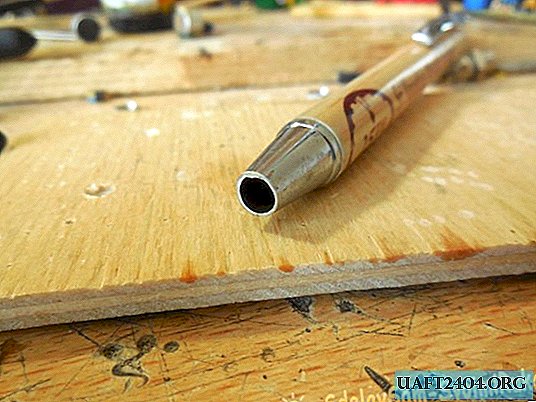

Using a core drill, we cut out two round blanks from a plywood sheet. Then we put them on the bolt, glue them together and pull them with a nut. Cut the size of the sandpaper tape and glue it to the sanding drum from plywood. At the time of gluing, we tighten the sandpaper with plaits.

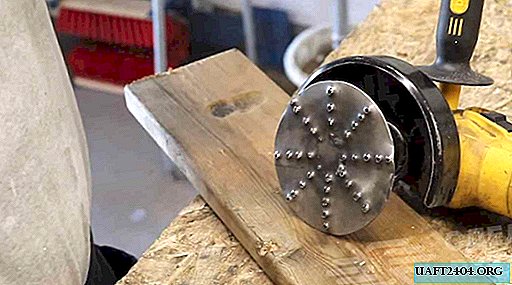

The resulting grinding nozzle is installed in the chuck of a network electric drill or screwdriver. Next, glue a wooden stand from pieces of plywood. For reliability, we fasten everything with self-tapping screws. We attach an electric drill to the stand with metal clamps.

To do this, first drill holes in the plywood, insert the bolts and fasten the lower parts of the clamps. After that, install a drill and fix the upper halves. Now the homemade product is ready for use. With this design, you can grind the ends of sheets of plywood and other sheet materials.