Drills for electric drills (primarily for metal drills) during daily operation - in particular, when working with solid materials, wear out very quickly and become dull. However, do not rush to throw them away for scrap, since you can return the drill to its original performance with sharpening.

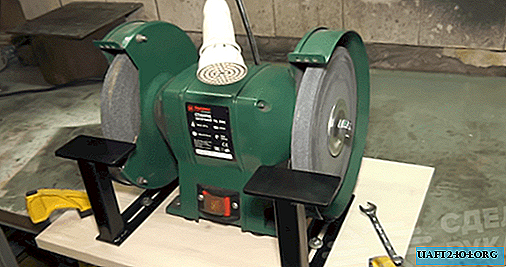

In the workshop and at home, drills for electric drills are best sharpened on emery machines equipped with a solid grinding wheel. If such a machine is not at hand, then you can use home-made devices for quick sharpening the cutting edge of the tool, which are easy to make with your own hands.

The main stages of work

We take a nut of suitable sizes, make markings and with the help of a grinder make cuts of a triangular shape. Next, weld a smaller diameter nut to it from above. After completing the welding work, it is necessary to clean the surface of the resulting part with a grinding disc to give it a more accurate appearance.

Then it remains only to pick up a bolt of suitable diameter and screw it into the upper nut. Now you can try this device in work. The drill is inserted into the triangular slots of the lower nut, and then clamped with a bolt. For sharpening, if there is no emery machine, you can use a grinder.

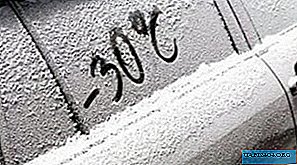

Please note that during sharpening, the edge of the drill cannot be overheated, otherwise the hardening of the metal can be "released", as a result of which the wear of the cutting part will occur faster. Therefore, you need to do several approaches for 2-3 seconds. As for the device itself, it is very convenient to use, and you can make it from improvised materials.