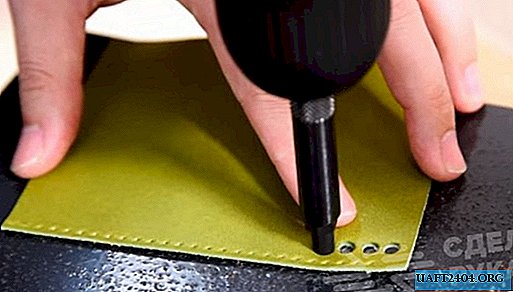

This homemade product is a versatile home mini-machine for the most comfortable work with leather products. The compact device can be used to create ridges, holes for punching, gluing and stamping any materials made of genuine and artificial leather.

Manufacturing process

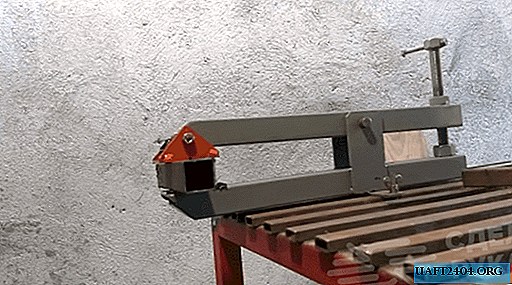

The basis of the entire structure is a wooden frame made of boards. The first board must be cut from two sides at a certain angle, using a specially prepared template for this.

Then, to the end part of the cut-off corner (on one side of the board), you need to "plant" a wooden square blank with four holes for the bolts on the glue, and fix it with self-tapping screws.

On the opposite side of the board you need to drill two holes, and then fasten this part with two other boards perpendicularly with bolts with washers and nuts. For greater reliability, the surfaces of the boards that are in contact with each other can be greased with any carpentry glue or PVA.

The total height of the structure should be approximately 31-32 cm. Two wooden stops in the form of triangles must be glued to the side surfaces of horizontal boards (beds). Next, you will need to install a steel clamp housing with a lever and a chuck from an electric drill or screwdriver.

How it works?

Thanks to its compact size, the universal manual press knife can be installed without problems, either in a small workshop or garage, or in an apartment, especially since this mini-machine works almost silently.

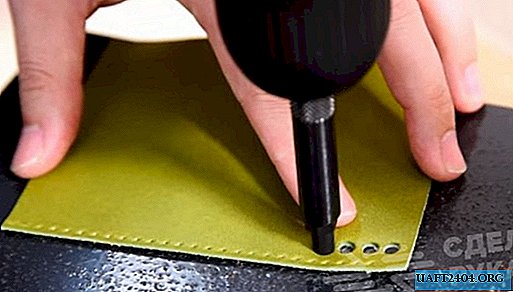

Punches, embossing tools and other leather accessories can be inserted into the cartridge. The detailed assembly process of this device, as well as its scope, can be seen in the video on our website.