Share

Pin

Tweet

Send

Share

Send

Therefore, cutting this material is not an easy task, and the tools for processing ceramic tiles should be even more durable and solid, made from special grades of steel or with diamond spraying.

But today there are many manual and electromechanical devices that allow working even with domestic ceramic tiles, cutting it not only along straight lines, but also along curved ones, including cutting square, rectangular, round, oval and curly holes.

Below we consider not the most difficult option: how to make a rectangular cutout adjacent to one edge of the ceramic tile, with special tools.

How to rationally cut tiles

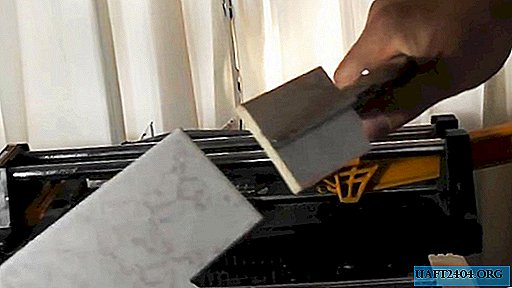

We assume that we have at our disposal a water electric tile cutter with a lower location of the electric motor. The cooling tank is located under the disk, and it partially immerses in it during operation.

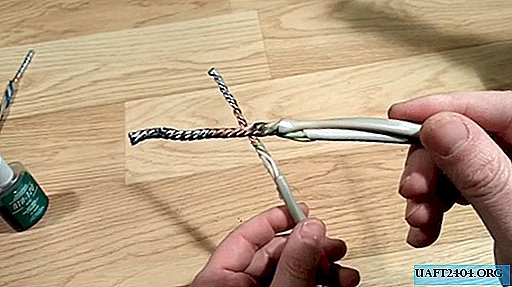

Will greatly facilitate the upcoming work manual tile cutter. Using it, you can make an incision in the glaze and break the tiles with special paws along the line of this incision. We will also need pliers.

Using a marker and a ruler, draw the outline of the planned cutout. Next, with the help of a water tile cutter and a disk for working with ceramic tiles, we cut two lines that are identical and parallel to each other and to the side faces of the line.

You can not be afraid that the disk will overheat or the tile will burst from thermal stresses. The working body, capturing water from the tank, cools itself and the place of cut, so the working temperature does not exceed the permissible value.

It remains for us to somehow remove the part of the tile between the two slots and the line that connects them. You can do this in various ways. But we will use a manual tile cutter, as we have it in stock.

Using its cutting roller, we draw a notch line along the glaze from one to the other slot made by a water tile cutter.

One could use the paws of the same tool to break off the “tongue”, contoured by two slots and one notch. But we will do a little different.

We will use the pliers that we have at hand. We grab the cutout filling with their sponges and slightly press on the handles.

A characteristic sound is heard, and an extra piece of tile remains in the lips of the pliers, breaking off exactly along the notch line.

Tips and Instrumental Variations

- To improve the quality and facilitate the work associated with cutting ceramic tiles, it should be kept in water for about 60 minutes before starting work.

- Other tools can be used to cut this and similar materials (porcelain stoneware, metlakh tiles, clinker, etc.): ordinary glass cutter, grinder, wire cutters, as well as home-made tools made from a drill and even a nail.

- When cutting tiles, especially porcelain, using a water tile cutter and, moreover, a grinder, it is necessary to use safety glasses, ear plugs and a respirator.

Share

Pin

Tweet

Send

Share

Send