Share

Pin

Tweet

Send

Share

Send

I am sure that at least once in your life you needed a portable 220 V generator. With the help of it you had to power something in conditions where a regular network is not available. In general, a gas generator itself is an extremely useful thing, and it can be useful even at home, taking into account not frequent, but there are blackouts for one reason or another.

It’s quite expensive to buy a new device, and if you have a broken trimmer with a working motor lying around in your workshop, you can use it and make a generator based on it.

Will need

- Gasoline engine from motokosa. It is advisable to use four-stroke models.

- As a generator, an engine from an electric lawn mower is used. He is quite capable of working in the opposite direction - to generate electric current. You can use other instances.

- A pair of pulleys.

- Traction belt

The idea

The idea is this: put the engines parallel to each other. A rotation to transmit by means of a belt drive.

Before the incarnation, I decided to check how the motor generates current from the lawn mower. I rotate its shaft of screwdrivers.

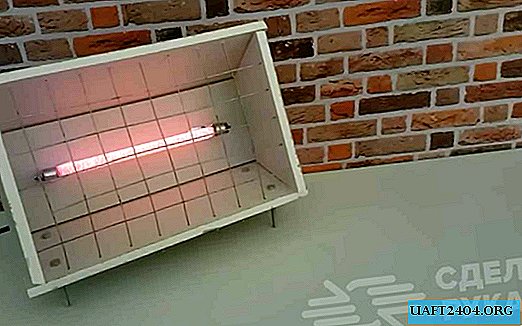

As you see, a 40 Watt incandescent lamp of 220 V is used as a load. Of course, a screwdriver cannot give those revolutions for sufficient reproduction, but the multimeter shows at a maximum of 156 Volts. But this is a preliminary result.

Making a gasoline generator from a scythe engine

We pass to the embodiment of the idea. First of all, we remove the flywheel casing with the mount, where the rod was inserted before and with the help of the grinder we saw off its nose to fully open the shaft.

A centrifugal clutch is assembled in the same assembly.

The size of this shaft must be selected and a pulley. Unfortunately, I did not find suitable ones. So I took the pulley and picked up a sleeve from the threaded connectors to it.

Checked how it will fit.

Grinder cut down too much.

With a round file, I grind the inner surface to size.

I drilled a hole on the side and cut the thread.

Picked up a bolt.

Then he sharpened the shaft on one side.

Dress the pulley and tighten with the side bolt.

We fasten the knot to the engine.

The pulley was matched almost exactly to the generator. Also, a hole was drilled from the side, a thread was cut and a bolt was picked up for fixation.

Now, from a galvanized profile, it was decided to make a frame. We make measurements and determine the size of the entire structure.

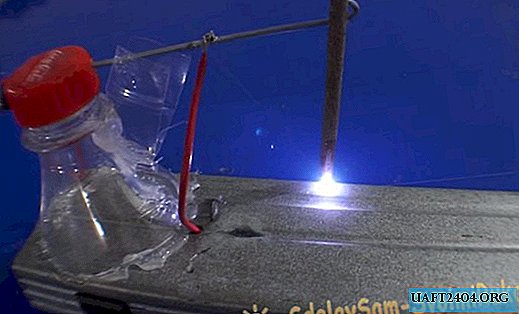

We weld the frame by welding. We drill holes for mounting the generator.

We fasten the engine mount to the screws.

And already the engine itself.

We fix the motor to the bolts with nuts.

Since the shaft of the gasoline engine experiences lateral load of the belt, it was decided to make additional oblique fastenings and weld them in the frame.

Dress the belt on the pulleys.

We disconnect the gas control cable. And the speed will be further regulated by the idle stock.

From the board we make the connection and control panel.

We fix a voltmeter, a network adapter and a button on it. We solder the wires from the engine responsible for the ignition to the button, so that when you need the engine you can stop it.

Check in work

We start the engine. By adjusting the idle speed, we set the output voltage at the generator output in the region of 220 V.

We connect various loads. The voltage drop is not significant.

I can’t say the power of the installation itself, but I think it’s quite possible to take 200-300 watts from it.

Share

Pin

Tweet

Send

Share

Send