Share

Pin

Tweet

Send

Share

Send

Will need

To make this craft, you will need only quite affordable materials and universal tools:

- piece of PVC pipe;

- pendulum, jigsaw, hand saw go mini-drill with a cutting disc;

- holder for rings, for example, pliers;

- a building hair dryer or any other suitable heat source;

- template for the formation of chain links of an oblong shape;

- a hairdryer nozzle in the form of a thin metal plate or knife blade.

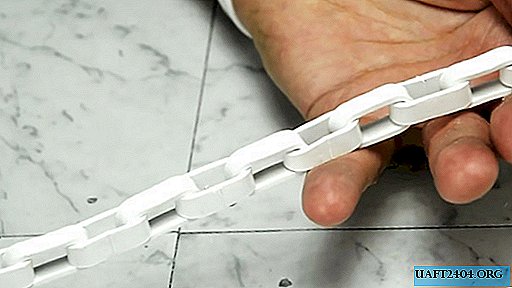

The process of manufacturing a plastic chain from a pipe

The manufacturing technology of the plastic chain is quite simple and obvious. We start by sawing a piece of the selected PVC pipe into rings of equal height. This is done using a mini-drill and a cutting disc, as well as a saw (pendulum, jigsaw or hand). You can also use any device that automatically ensures cutting the same height rings.

Having made the necessary number of blanks for future links, we proceed to the removal of traces of cutting and grinding of their ends. To do this, we use the appropriate tool equipment suitable for such an operation (emery wheel, grinding disc, grinder, etc.).

We string several rings on a suitable object, for example, round-nose pliers and blow them with hot air from a building hair dryer until the material softens and begins to plastically deform.

Immediately place the heated rings on the template to get an elongated shape and hold them until the links solidify in their new appearance. To do this, gently press them with your fingers wearing gloves.

We carry out a cross-section in all elements with a thin disk mounted on the spindle of a mini-drill.

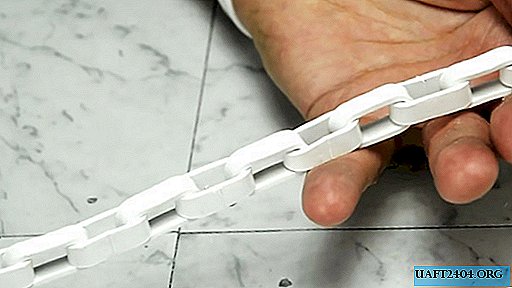

Using cuts, we connect the individual links into a common chain.

We weld the sections, preheating the junction with a thin blade or scalpel, which receive thermal energy from a suitable source (hair dryer, open flame, etc.).

To do this, we place the heated blade in the incision until the surfaces to be joined soften and, when pressed, join. We maintain compressive strength for some time.

The process of heating and welding the links of the plastic chain proceeds quite quickly. It lasts just a few seconds due to the small area of contact (heating) and large - heat dissipation (cooling).

Share

Pin

Tweet

Send

Share

Send