Share

Pin

Tweet

Send

Share

Send

If there is a tie-in of two pipes of the same diameter, then on the plunge we perform the so-called. "pants" - segments that for the most part should have a size three times smaller than the diameter.

Below, we consider the most difficult case in terms of cutting, when the cut-in pipe is slightly smaller in diameter than the main one, for example, 89 mm or 76 mm and 100 mm, respectively.

Will need

In order to cut and brew an insert of two metal pipes of different diameters, we must have:

- pipe blanks of two different diameters;

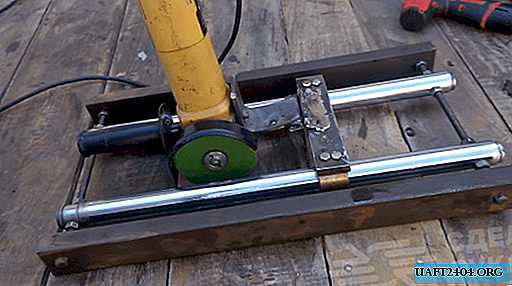

- a grinder with a cutting and grinding wheel;

- marker;

- ruler, square;

- welding machine;

- hammer.

Round pipe insertion algorithm

We will use the widely used technology of collar tie-in when the edge of a cut-in perpendicular to a round pipe is formed with respect to the main pipe. We will adhere to the following order, implementing this method.

We cut the edge of the welded pipe at a right angle.

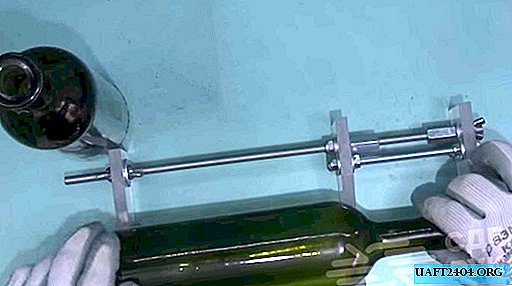

We mark four points on it, which are the intersection points of two mutually perpendicular diameters and the pipe end. If everything is done correctly, then these points are arranged evenly in a circle through 90 degrees.

We place the pipe with the marked end to the side surface of the main one and measure with the help of a metal ruler or tape measure the largest gap between the end face of the first and the second generatrix. In our case, it turned out to be equal to 30 mm.

From two opposite points at the ends we lay down along the generatrix of 30 mm. We draw a marker on the side surface of the pipe with two smooth lines emanating from one adjacent point on the end, in opposite directions, so that they pass through the lower marks and converge at the second point on the end.

According to the markup, using a grinder with a cutting disc, cut out fragments in the form of two identical rounded segments. We cut out the curly cuts at the end of the pipe so that there are no burrs or bumps left.

We try on the pipe in place and, if an insufficient fit is found, we correct these places with a grinder and achieve a more exact coincidence of the pipe surfaces.

We transfer the external contour of the welded pipe to the side surface of the main one with a marker. Inside the obtained closed line, we build a congruent line, departing from the outer one by the thickness of the pipe wall. It is on the new line that we will produce the cut.

Using a grinder, cut a circle in the pipe according to the marking and process the edges to remove burrs and round the edges for welding.

Before starting welding work with a square, we check the perpendicularity of the pipes. The angle between the generators should be 90 degrees. We do oven mitts in two or three places.

We start welding from the lower point of contact and carry out in two passes with a filament seam: root and facing. In this way, we will ensure the best quality of the welded joint.

When welding, it is important to choose the right current strength, which depends on the quality of the supplied electricity and, in particular, the voltage. Usually we are talking about 70-80 A. We cook with a three-millimeter electrode UONI-13-55, trying to ensure that the slag does not fall into the metal.

Having passed from the lower point to the upper, we stop and beat the slag with a hammer. The discovered shortcomings are uncritical, because they can be eliminated in the second pass - facing.

In the same way, we weld the other half of the joint of the surfaces of the pipes. After that, slightly process the first seam, removing large flows and slag.

We begin to impose the front seam from the bottom, holding the electrode at an angle of 45 degrees along the way, and moving it transverse to the first seam, or "herringbone". Next, we cook the seam, holding the electrode almost vertically to the surface, and finish the first half, placing the electrode again at 45 degrees along the way, and making circular motions.

We begin to impose the front seam also from the bottom point and bring it to the top, after which we beat off the slag with a hammer from the seam.

Similarly, we cook the front seam in the second half of the contact of the pipes. As you move up, we slow down the welding speed so that the seam is the same everywhere.

We also beat off the slag and clean the seam with a grinder. The result is a neat and reliable welding seam.

Share

Pin

Tweet

Send

Share

Send