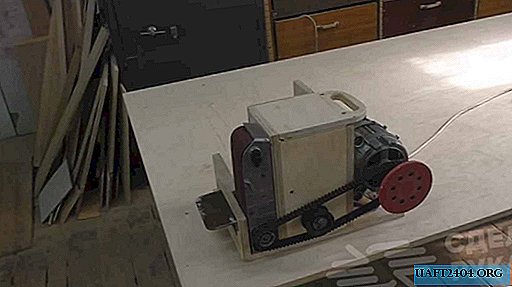

Grinder is a grinding and grinding machine with belt abrasive. Such a stanochka will always come in handy both in the home workshop and in the garage.

In this case, the author uses a motor from an automatic washing machine as a drive. The advantage of this engine is that it has compact dimensions and also connects to a 220 V network.

However, there is a drawback - high speeds, which are not needed for the grinder. In any case, 14 thousand revolutions is a lot.

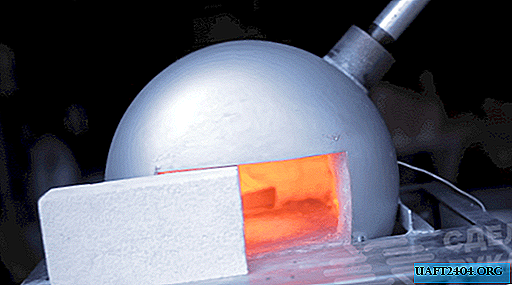

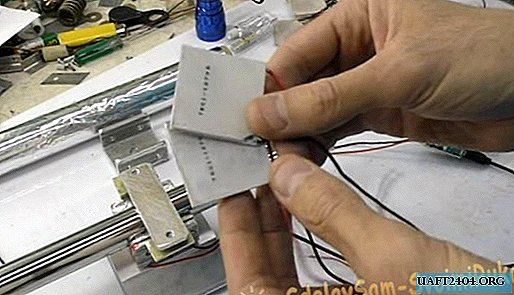

However, this problem can be solved by ordering on the Internet a board for adjusting engine speed, which allows you to lower the speed without losing power.

Design features

To make a home-made grinder, the master will use the sole of the old belt sander. This is convenient because sanding belts can be bought ready-made, rather than glued them yourself.

The transmission mechanism will be belts and rollers of the drive system of auxiliary units of the car. Please note that the timing belt is notched, but in this case, the master will not use the notched, but the smooth side of the belt.

The main stages of work

First of all, the author makes a leading pulley. And for this he uses plywood 20 mm thick. We make a marking and cut out a circle of the required diameter with a jigsaw. Then you need to drill a hole in it.

The pulley will need to be mounted on the motor shaft, for fixing the author uses glue. Then you will need to connect the speed control.

The diameter of the pulley from plywood turned out to be a little large, and therefore the author grinds off excess with the help of a joiner's cutter. As a result, the diameter was reduced to 70 mm, and the runout was minimized.

Grinder assembly process

At the next stage, the author cuts a piece of plywood 18 mm thick, to which an electric motor is attached. For fastening the master uses furniture corners.

The sole of the grinder must also be secured to the plywood. Then we fix the platform with the engine and the platform with the sole to the base. Between them, the author provided a box in which the electronics will be located.

To fasten plywood to each other, the author uses two types of fasteners: confirmats (euroscrews) and dowels. As a result, the design is quite rigid.

Next, a roller is installed - an eccentric belt tensioner. Then the author makes and fastens the lid with a handle so that it is convenient to carry the machine.

At the next stage, the author fastens the side cover of the box, on the front side of which displays the speed control and LED.

The final touch - and you're done!

If desired, you can expand the capabilities of the grinder. To do this, screw a part such as a flange to which a piece of the stud is welded to the leading pulley from plywood. A Velcro disc is put on it.

Now it remains only to make a persistent table. In this case, it will be mobile. For its manufacture, the master used a piece of plywood and a piece of metal corner.

Details on how to make a mini grinder with the engine from the washing machine, you can see in the video on our website.