Conventional calipers are not designed for marking, since over time the jaws of the tool grind. However, out of the ordinary, you can make a caliper. This will require a minimum of tools and materials.

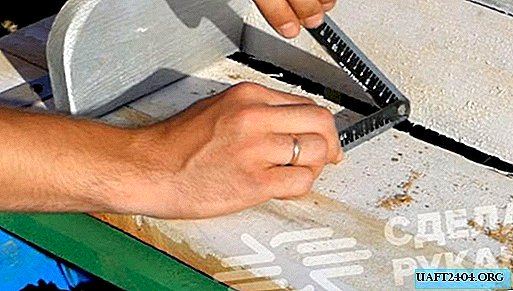

In order to modernize the old vernier caliper, first of all, it is necessary to cut off part of the jaws, and grind the place of the cut.

You will also need two carbide inserts (triangular in shape) from the turning tool. They will be used as tips to attach to the tool jaws.

The main stages of work

At the next stage of work on each carbide plate, it will be necessary to grind the upper plane. For this, the master uses a diamond blade.

Next, you need to grind the sides of the plates so that all sides of the triangle are ultimately smooth. Thus, you get 3 cutting edges. Be sure to use a respirator to protect your respiratory system from fine metal dust.

Then, holes must be drilled in the caliper jaws to secure the plates. Please note that the steel is hardened, so first you need to make its vacation.

The master heats the sponge red-hot and allows it to cool. And then only you can start drilling. At the last stage, it remains only to cut the threads in the holes and screw both plates to the jaws.

In detail about how to make a marking out of the most ordinary caliper, we recommend that you look in the video on the site.