Using a home-made universal machine, made on the basis of a screwdriver, you can edit kitchen or hunting knives at home, as well as other cutting tools (for example, carpentry chisels). Of course, you will not get the perfect sharpening, but you can “freshen up” the dull edge of the blade.

The design of the machine is very simple, therefore, making such a device is possible for everyone. Alternatively, an electric drill can be used as a drive instead of a screwdriver. This machine works on the principle of reciprocating movements - for this it will be necessary to make the simplest eccentric.

Why is the machine considered universal? Because you can install a grindstone on it, as well as a wooden block with an emery cloth - for grinding workpieces or wooden parts. To make the base and other structural elements, you can use unnecessary trimmed boards or pieces of plywood.

The main stages of work

Using a crown on a tree, we cut out a round part and make an eccentric out of it. To do this, we additionally drill a hole with an offset from the center, into which we insert a bolt.

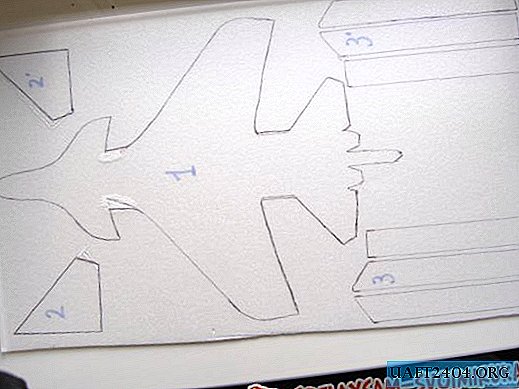

Then it is necessary to make a longitudinal groove in the wooden block along which the eccentric shaft will move.

You also need to make another such block with a longitudinal groove, which will move back and forth - a grindstone or a block with sandpaper is installed on top of it. After that, we proceed to the assembly of the entire structure.

The detailed manufacturing process of a universal machine tool from a screwdriver for straightening knives or grinding parts can be seen in the video on the website.