To sharpen a kitchen knife, a lot of mind is not necessary. It is enough to have a hand-made knife sharpener made of available materials on hand. For example, for the simplest budget option, carbide cutting wheels from a conventional glass cutter will be required. Moreover, the more there will be, the better.

You will also need a foundation on which these same videos will be placed. An aluminum plate of suitable sizes can be used for this. In principle, a rectangular or square billet made of other available materials (for example, wood, fiberglass, plywood) is suitable.

The main stages of work

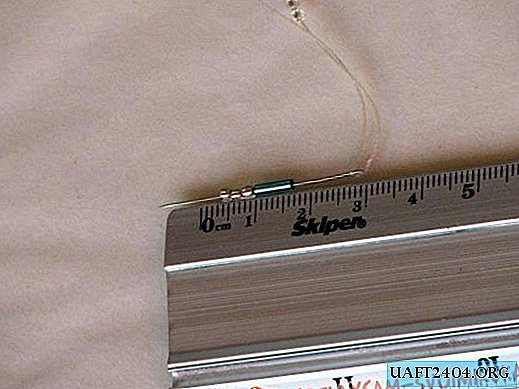

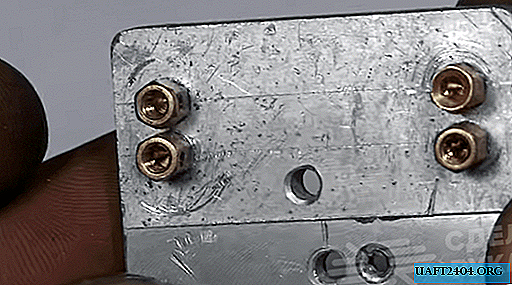

In addition to the above materials, for the manufacture of homemade knife sharpeners will also require brass racks in the amount of four pieces. They need to drill one hole with a diameter of 1-2 mm. Please note that only one of the rack walls needs to be “perforated”.

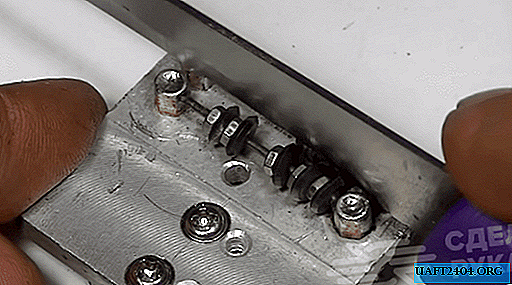

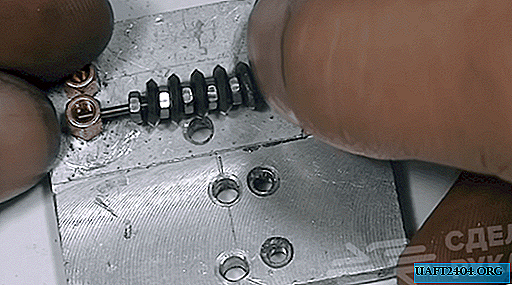

Then we drill four holes in the base of the sharpener, cut the threads in them and install brass posts. After that, we put the prepared cutting rollers from the glass cutter on two studs 1 mm thick, alternating them with nuts. Whenever possible it is better to use studs made of spring steel.

In the next step, we install studs between brass racks. For rigid fixation of the studs, solder the holes in the racks with tin-lead solder.

Then it remains only to attach the base to the wooden handle of the glass cutter. The result is the simplest home-made sharpener for quick editing of kitchen knives.