Making your own reliable and powerful bench vise that will be convenient in operation is not at all difficult, as it might seem at first glance. And for the manufacture of a vice for a garage or a home workshop, you can use any improvised materials that are at hand.

As practice shows, in most cases the need for homemade bench vice is caused not so much by the desire to save on the purchase of a factory model, but by the need to have at hand a universal clamping device adapted for specific tasks.

The main stages of work

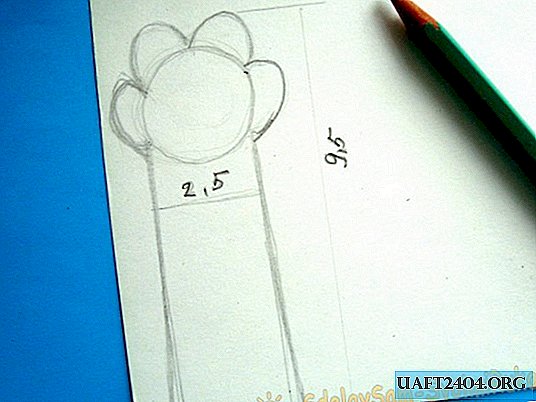

First of all, it is necessary to prepare the basic materials and blanks, from which homemade bench vice will then be assembled. For work, you need steel plates of different sizes, an M16 threaded rod with nuts and washers, a 40x30 mm profile pipe (three millimeters thick) and two old files

A piece of strip (from the profile pipe) is welded to the square plate, and 2 nuts for the diameter of the stud, which in this case will serve as a screw, are welded to it. Then we drill four holes in the corners for attaching to the table.

Next, we weld two wide plates to the base, and between them a narrow one. A profile pipe should freely enter the formed opening, but at the same time it should not “walk”. That is, the backlash should be minimal.

An additional platform from the plate can be welded on top of the vise carriage, where, if necessary, you can align the nail or flatten the edge of the tube. Lastly, clamping jaws are made. You can see the step-by-step process of assembling homemade bench vice in the video on the site.