From an old screw jack, which is no longer suitable for lifting a car, but is still in working condition, you will get a very powerful and reliable home-made clamp. It is definitely useful in a home workshop or garage. The width of the workpiece is about 155 mm, so a clamp made of a screw jack can be used to fix the profile pipes 150x150 mm.

The main stages of work

The first step is to disassemble the mechanical jack into its constituent elements. Next, with the help of a grinder, we cut out the excess parts from two parts, after which we weld them together and we get one of the main components for the future home-made device.

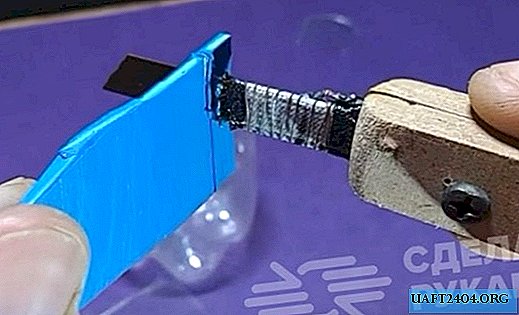

The second structural element is made of the two remaining parts. Four studs must be cut to size with a grinder, and then we weld them to the clamping parts of the main elements of the device. We clean the parts from traces of welding and paint with spray paint from a spray can.

The jack screw must be cut to the desired length, and then you can proceed to the final assembly of the entire structure. The fixture handle can be made from a piece of steel rod or smooth reinforcement of suitable diameter, on the edges of which two hex nuts must be welded.

To summarize

In general, a very good clamp was obtained from the old screw jack, which compares favorably with conventional clamps with a wider grip and greater clamping force. To make the improvised device last longer, the bearing must not be placed on the handle, but on the side of the screw. You can also make and screw clamping jaws.