If you need simple quick-clamping clamps of a G-shape with an eccentric mechanism in your workshop, you can make them yourself from improvised materials. Such homemade clamps will cost less than factory clamps. Moreover, they can be made for any size.

For the manufacture of G-shaped clamps with an eccentric, we will use segments of a square profile pipe 20x20 mm and 15x15 mm, a bolt with an elongated nut M8 or M10, as well as a “piglet” with a diameter of 25 mm from the steel round timber. From the main tool for work, you will need a grinder and a welding machine.

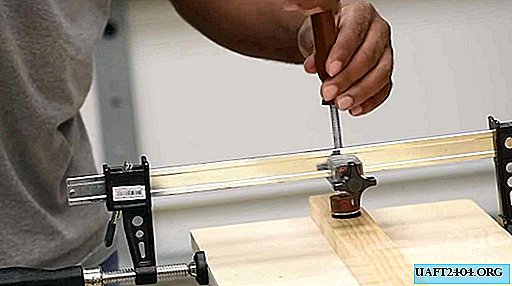

Clamp making process

First of all, we cut the profile pipes into the blanks of the desired length with a grinder. In a section of the profile 15x15 mm, insert a steel square and scald it from two sides. At the end, you will need to weld a round "patch". In another piece of 25 mm round timber, which will be an eccentric, we drill a hole.

In a profile pipe of 20x20 mm, you need to make small slots under the eccentric to slightly "drown" it. The remaining sections of the 20x20 mm profile are cut on one side at an angle of 45 degrees and welded together. Grind the weld points. We also weld a lever handle made of a steel bar of a suitable diameter to the clamp eccentric.

After that, it remains only to weld a nut with a bolt to the upper part of the clamp. We also weld perpendicularly a steel bar to the bottom of the bolt. The home-made G-shaped clamp with an eccentric turned out to be compact, light and very convenient to use. The main stages of work can be seen in the video on the site.