For more convenient processing of small metal blanks, the author proposes to make a do-it-yourself simple home-made clamp. To do this, he uses two stainless steel plates (halves of medical tweezers).

First of all, it is necessary to align both plates with a hammer. Then the master drills two holes in the plates with a drill with a diameter of 1.5 mm.

In the case of stainless steel, use more grease and drill at low speeds. After the holes are drilled, it will be necessary to cut off the strip from a piece of aluminum with dimensions of 15 * 70 mm.

The main stages of work

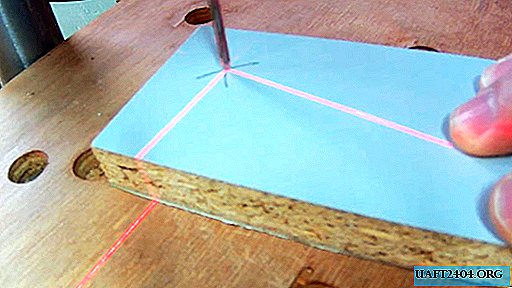

Then the strip must be cut in half, and on each workpiece using a hand saw for metal or a drill to make notches.

As you might have guessed, these two aluminum parts will be used as clamping jaws. They are mounted on the edges of stainless steel plates with two screws.

Also, it will be necessary to drill another through hole with a diameter of 6 mm in the stainless steel plates. Drilling is preferably performed on a drilling machine or drill with a drill stand.

Additionally, you will need to make a brass spacer sleeve. When all the parts are prepared, you can begin to assemble the device.

For details on how to make a simple home-made clamp for processing small parts, see this video.